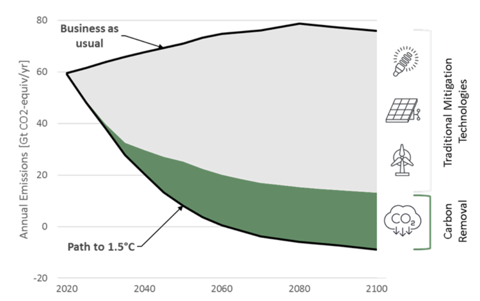

The science is clear

In addition to decreasing emissions, we need to remove CO2 that we’ve already emitted, to prevent climate change from continuing to harm our planet. And we need to do it now.

Why DAC?

Direct Air Capture (DAC) is one of the most promising technologies to remove CO2 due to its ability to verifiably and permanently sequester CO2 for millennia.

But there’s a catch – DAC is currently too complex, too expensive, and not deployable at great scale.

How are we different?

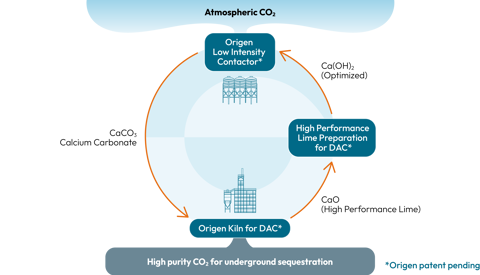

We designed a simple solution to minimize the risks associated with direct air capture. Here's how:

We own the

full loop

Core elements of limestone-based DAC are kiln and contactor. We own both.

Our contactor is

low intensity

Enabled by our optimized lime production and processing

We utilize scalable and

cost effective inputs

Limestone and thermal energy molecules that are available widely and today

Our solution is

permanent

Scientifically proven to lock away CO2 for over 1,000 years